Concrete Pour

The construction technology of the concrete beds using the mixing equipments of the pull-shovles, Hopper Cars, and suit.

An outline of the new technology

The details of the new technology

- With regard to the construction of the concrete roadbed tracks of the double track railroads, in case a ready-mixed concrete truck cannot directly enter, the direct placement of the onsite concrete roadbeds has become possible by using the movable machine devices.

- There is no blocking phenomenon in the conveying pipes. And the supply and demand of the equipment are smooth. And the construct ability has been improved through the securing of the stability of the equipments in the curve sections.

- The improvement of the work environments within the tunnels through the reduction of the washing water of the conveying pipes, the exhausts within the tunnels, etc.

- The reduction of the construction costs because the central access road is unnecessary compared to the placement method of the access road for the vehicles.

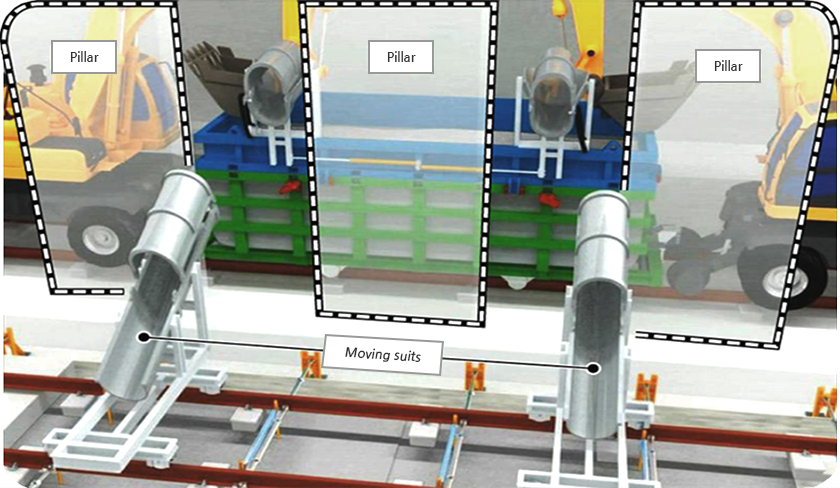

[ Outline figure of the construction method: The mixing equipments of the pull-shovels, Hopper Cars, and suits. ]

[ Outline figure of the construction method: The mixing equipments of the pull-shovels, Hopper Cars, and suits. ]

[ Moving suit equipments ]

[ Moving suit equipments ]

The onsite applicability

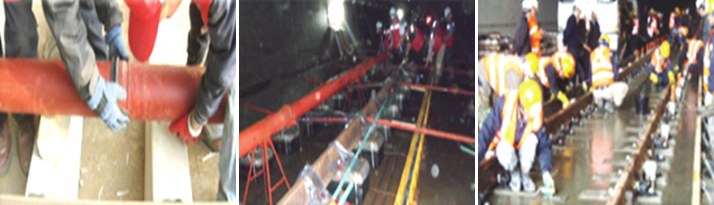

The construction order figures.

-

①The supply of the ready-mixed concrete with the Hopper Cars

-

②The entry of the Hopper Cars into the placement site

-

③The installation of the suits

-

④The supply of the ready-mixed concrete utilizing the backhoes

-

⑤The work of the sides organization of the roadbed sides

-

⑥Completed tracks

The construct ability

| Category | Previously existent technology Ⅰ [The method of placing the conveying pipes] |

Previously existent technology Ⅱ [The method of placing onsite] |

The new technology |

|---|---|---|---|

| The ease of the transportation |

|

|

|

| The ease of the placement |

|

|

|

The safety

| Category | Placement preparation work and the safety when placing |

|---|---|

| The ease of the transportation |

|

| The ease of the placement |

|

TOP

TOP